CFD Simulation of Cement Pre-calciners with STAR-CCM+

- Alvaro Filho

- 2 hours ago

- 5 min read

Cement production is one of the most energy-intensive and emission-intensive industrial activities, accounting for approximately 5% to 8% of global CO₂ emissions. In the modern dry manufacturing process, the pre-calciner plays a central and critical role, being the equipment where most of the limestone calcination occurs (decomposition of CaCO₃ into CaO and CO₂) and where between 55% and 65% of the system's total fuel is consumed.

The efficiency of this equipment depends on a delicate thermodynamic balance between two main reactions: fuel combustion (exothermic process) and raw material decomposition (endothermic process). Due to the complexity of multiphase flow, where solid and gaseous phases interact at high speeds and temperatures, physical experimentation on an industrial scale is extremely costly and often impractical for detailed internal measurements.

In this context, Computational Fluid Dynamics (CFD), with STAR-CCM+, emerges as an essential tool for the optimization and design of these reactors. Through numerical modeling, it is possible to predict the hydrodynamics of the flow, heat transfer, chemical kinetics, and emissions, critical factors that act in the pre-calciner.

Challenges and Solutions in Pre-calciner Simulation

CFD simulation of pre-calciners presents challenges associated with the multiphase, thermal, and reactive complexity of the process. The cohesion and agglomeration of fine raw meal particles significantly alter the flow and calcination efficiency, requiring advanced particulate phase models. On a larger scale, the formation of gas-solid clusters introduces heterogeneities that render homogeneous drag models inadequate.

Heat transfer constitutes another critical point, due to the very thin thermal boundary layers along the walls, whose correct mesh refinement is unfeasible in complete industrial geometries. As a solution, coupling CFD with simplified mechanistic models allows for realistic thermal estimates with reduced computational cost.

Furthermore, the strong coupling between exothermic and endothermic reactions imposes high nonlinearity on the system. In the context of emissions reduction, oxy-fuel combustion presents additional challenges, such as ignition delay and high CO₂ concentrations, which can be mitigated by multi-stage combustion and pre-gasification strategies, ensuring operational stability and low NOx levels.

CFD Simulation of the Pre-calciner

This numerical simulation study, developed in STAR-CCM+, focuses on the detailed analysis of combustion in a large-scale cement pre-calciner, emphasizing the evaluation of the characteristics of the oxy-fuel process and its impacts on the thermal efficiency and operational stability of the equipment.

The modeling was conducted using a non-premixed combustion model, incorporating the chemical kinetics of coal, devolatilization phenomena, NOx formation, and thermal radiation effects. The kinetic mechanism employed is presented in Table 1. It should be noted that, in this study, the particulate model of calcium carbonate (CaCO₃) was not considered, focusing the analysis exclusively on the combustion of the solid fuel.

Reaction | Equation |

R1 | 2CO+O2->2CO2 |

R2 | C + 1.5 O2 -> 0.5 CO +0.5 CO2 |

R3 | C + CO2 -> 2CO |

R4 | CaCO3 -> CaO + CO2 |

R5 | Devolatilization |

Table 1. Chemical Reactions

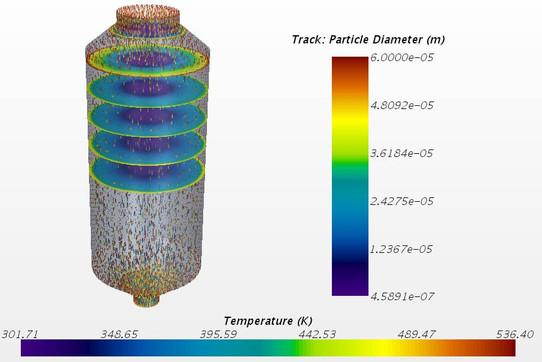

The numerical model adopted the following simulation assumptions: steady-state regime, ideal gases, Eddy Break-Up (EBU) combustion model, k-ε Realizable turbulence model, thermal NOx model, and coal particles modeled in a Lagrangian fashion, with an average diameter of 50 μm.

The computational mesh was strategically refined in regions of higher thermal and chemical gradients, such as the primary and tertiary air intake zones and coal injection zones. Boundary conditions were defined to reproduce real operational scenarios, including prescribed air and fuel flow rates, ensuring greater physical representativeness of the model.

Figure 1. Geometry and computational mesh

Figure 2 shows the temperature field inside the pre-calciner. It can be observed that the regions near the central axis of the flow reach temperatures above 2100 K, evidencing intense combustion activity. In contrast, a low-temperature zone is identified near the inlet nozzles, associated with the high concentration of air in these regions, which promotes dilution of the fuel mixture and locally reduces thermal efficiency. The analysis of the thermal field allows us to assess whether the regions of interest operate within the appropriate temperature range for the process.

Figure 2. Temperature profile

Complementing this analysis, Figure 3 presents the axial temperature profile along the pre-calciner. A thermal peak is observed in the first 10 meters, resulting from the initial combustion reactions of the coal, followed by a gradual reduction in temperature along the flow, as the fuel is consumed and the gases are diluted.

Figure 3. Temperature plot

Figure 4 illustrates the concentration profiles of CO, CO₂, and O₂ along the height of the pre-calciner. The CO₂ concentration progressively decreases as the gases rise, reflecting chemical interactions and flow dilution. CO shows peaks near the burner region, associated with centralized coal injection and incomplete combustion. Due to the low local availability of oxygen, some of the CO is not oxidized to CO₂, resulting in a lower CO₂ concentration at the equipment outlet.

Figure 4. Concentration profiles: (a) CO; (b) CO2; (c) O2

Figure 5 shows the evolution of the molar fraction of the main components along the vertical axis of the pre-calciner. A significant consumption of O₂ and CO₂ is observed, concomitant with the generation of species such as volatiles, CO and H₂O, characterizing the dominant stages of the coal combustion process.

Figure 5. Molar fraction plot

Finally, Figure 6 presents the velocity field and streamlines, highlighting the direct influence of the pre-calciner geometry on the flow. Recirculation zones near the tertiary air inlet are prominent, as are regions of low turbulence ("dead zones"), which represent potential areas for the accumulation of unreacted material. Although these regions are associated with flow separation, they also play a relevant role in the conduction and mixing of gases. These results indicate the need for geometric adjustments to optimize the flow, reduce energy losses, and improve the overall efficiency of the equipment.

Figure 6. Velocity Profile

Conclusion

The results presented demonstrate that the use of STAR-CCM+ as a Computational Fluid Dynamics (CFD) platform for the integrated analysis of fluid dynamic, thermal, and reactive phenomena governing the performance of cement pre-calciners is effective. The robustness of the software allowed for consistent modeling of non-premix combustion, species transport, thermal radiation, and particulate behavior, enabling a faithful representation of industrial operating conditions.

The adopted approach proved particularly relevant in the context of Oxy-Fuel combustion, where the coupling between chemical reactions, heat transfer, and particulate dynamics imposes additional challenges. The use of appropriate models makes it possible to evaluate operating and design strategies, such as the optimization of air and fuel injection, geometric adjustments, and burner configurations, aiming at reducing emissions, increasing energy efficiency, and greater operational robustness.

In this way, CFD simulation is consolidating itself as a strategic tool for decision-making, retrofitting, and developing new technologies in cement plants, reducing dependence on empirical testing and accelerating the transition to more efficient and environmentally sustainable processes.

References

ZHENG, Qiang et al. CFD simulation of a cement precalciner with agglomerate-based drag modeling. Powder Technology, v. 436, p. 119508, 2024.

ZHANG, Leyu et al. Numerical simulation of oxy-fuel combustion with different O2/CO2 fractions in a large cement precalciner. Energy & Fuels, v. 34, n. 4, p. 4949-4957, 2020.

KANELLIS, Georgios et al. CFD modelling of an indirectly heated calciner reactor, utilized for CO2 capture, in an Eulerian framework. Fuel, v. 346, p. 128251, 2023.

HAIJIAN, Dou; ZUOBING, Chen; JIQUAN, Huang. Numerical Study of the Coupled Flow Field in a Double-spray Calciner. In: 2009 International Conference on Computer Modeling and Simulation.

SHU, Yixiang et al. Numerical study on oxy-fuel combustion of coal pre-gasification products in cement calciner. Applied Thermal Engineering, p. 126901, 2025.

MIKULČIĆ, Hrvoje et al. Numerical analysis of cement calciner fuel efficiency and pollutant emissions. Clean technologies and environmental policy, v. 15, n. 3, p. 489-499, 2013.

If you are looking to increase the thermal efficiency of your pre-calciner, reduce emissions, and make more informed engineering decisions, CAEXPERTS can help with advanced CFD solutions using STAR-CCM+. Schedule a meeting with us and discover how to apply numerical simulation to optimize your cement production process and accelerate results with lower costs and greater reliability.

WhatsApp: +55 (48) 98814-4798

E-mail: contato@caexperts.com.br