CAEXPERTS 2025 Retrospective – Part 1

- Jan 6

- 3 min read

Throughout 2025, CAEXPERTS published a series of technical articles reflecting an increasingly clear scenario: computational simulation has ceased to be merely a support tool and has taken on a central role in modern engineering. Whether to increase the reliability of critical systems, reduce development costs, meet regulatory requirements, or explore innovative solutions, simulation was present in virtually every challenge addressed throughout the year.

This retrospective brings together the posts that stood out most in 2025, considering technical relevance, industrial applicability, and reader interest. More than a ranking, it offers a consolidated view of how different numerical methods—such as CFD, FEA, FSI, DEM, and SPH—were applied to solve real-world problems in diverse sectors.

This Part 1 presents the articles ranked from 10th to 6th place. They demonstrate the breadth of simulation applications, ranging from electric mobility and medical devices to industrial processes and high-performance products.

With the advancement of electric mobility, concern about the safety, reliability, and lifespan of batteries is also growing. This post explores how multiphysics simulation allows for the anticipation of failures, evaluating phenomena such as heat generation, aging, degradation, and extreme operating conditions. By predicting problems during the design phase, engineers can reduce risks, increase safety, and make more informed decisions throughout the product lifecycle.

In biomedical applications, small uncertainties can have large consequences. In this content, we show how Fluid-Structure Interaction (FSI) simulation is used to analyze peristaltic pumps employed in dialysis processes. By simultaneously considering fluid flow and component deformation, it is possible to reduce the risk of hemolysis, increase performance predictability, and raise the safety level of the device.

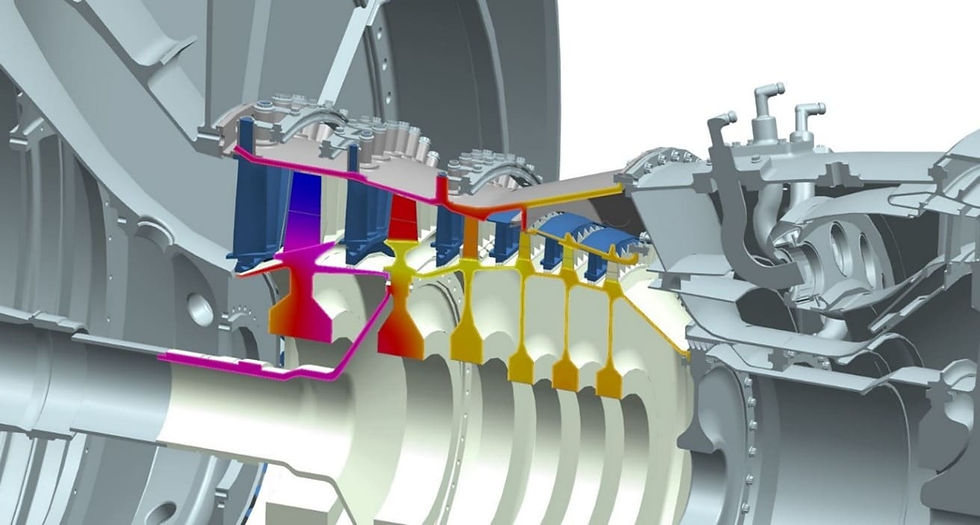

In gas turbine engineering, seemingly small geometric tolerances can have a significant impact on performance and efficiency. This post shows how simulation helps to understand the effect of clearances on losses, aerodynamic efficiency, and component lifespan, supporting more robust design decisions and avoiding surprises during testing or operation.

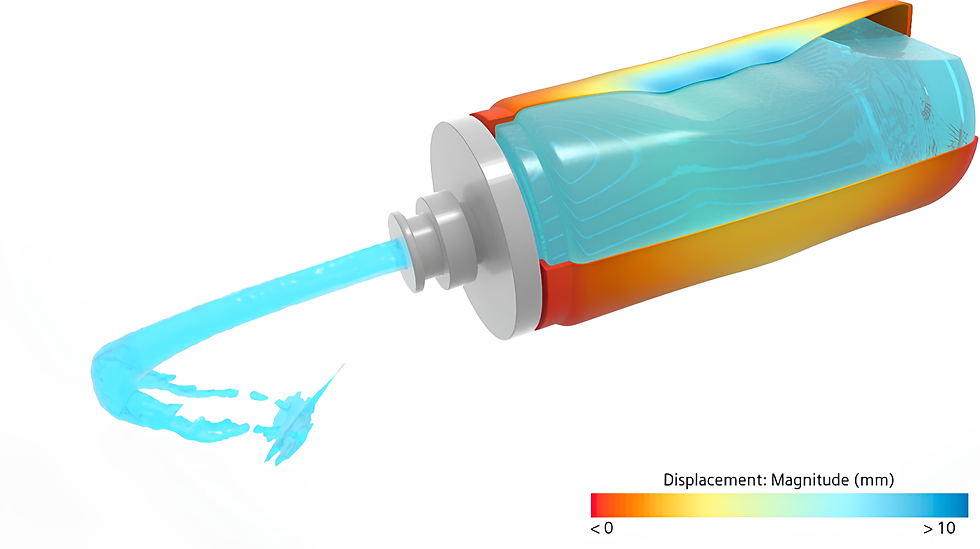

Simulation also finds its place outside the traditional industrial environment. In this article, CFD techniques are applied to the design of hydration bottles for cycling, evaluating aspects such as flow, ergonomics, and aerodynamics. A clear example of how engineering fundamentals can be used to optimize everyday products, where performance and user experience go hand in hand.

Processes such as painting and bottling involve multiple physical and operational interactions. The Virtual Body concept allows for the integrated simulation of these processes, anticipating problems, reducing rework, and optimizing material consumption. This content reinforces how simulation can increase efficiency, quality, and competitiveness in complex industrial environments.

In Part 2 of the retrospective, we will present the content ranked 5th to 1st – posts that stood out for their high technical impact and direct application in critical energy systems, thermal processes, and structural engineering. Don't miss the continuation of this retrospective!

The CAEXPERTS team wishes everyone an excellent end to 2025 and a Happy New Year. May 2026 be marked by new projects, technical achievements, and increasingly innovative solutions. Thank you for following us throughout this year and for trusting in our content and expertise.

Let's build the next challenges together. If you're looking to make safer engineering decisions, optimize designs, and reduce uncertainty throughout product and process development, talk to CAEXPERTS. Our expertise in computational simulation can help transform complex challenges into intelligent, efficient, and reliable solutions. We're ready to support your engineering in 2026 and beyond.

WhatsApp: +55 (48) 98814-4798

E-mail: contato@caexperts.com.br