CFD Simulation of Bioreactors with Simcenter STAR-CCM+

- Sep 26, 2024

- 5 min read

Characterization and Optimization of Flows in Bioreactors

The design of bioreactors presents challenges that go far beyond those of conventional reactors due to the use of living cells and microorganisms. The characterization and optimization of currents and flows in these equipment, as well as the adequate control of flow speed, concentrations and temperature, for example, are essential points that require a lot of attention from bioreactor engineers and operators.

Microorganisms (animal cells, plant cells, bacteria, fungi and viruses), often used for the production of modern pharmaceutical and cosmetic compounds, are particularly sensitive to chemical and physical stresses. The homogeneity of the mixture, adjusted by the rotation of the impeller, is important to avoid chemical stress, while physical stress can be controlled by balancing the agitation and avoiding shear stresses that harm the organisms.

Therefore, bioreactors and fluid flows within the tank must be well characterized. If key engineering parameters such as energy consumption, mixing time, and mass transfer coefficient (oxygen) are well known, it is possible to optimize the growth and productivity of organisms while maintaining high product quality. In addition, trial and error experiments, which are time-consuming and cost-intensive, can be reduced, which is especially important if the availability of biological material is limited, as is the case with primary tissues or stem cells.

Challenges on an Industrial Scale

Understanding and correctly modeling the complex interactions between biological and hydrodynamic phenomena is essential in bioprocesses. When scaling up a bioreactor from laboratory to industrial scale, it is common to observe a decrease in productivity. This is usually due to the decrease in mixing efficiency as the reactor size increases. With increasing volume, steep gradients of substrate, dissolved oxygen and pH arise, which can alter biological responses, both in terms of physiology and metabolism, compared to small-scale cultures.

Another important challenge is the shear forces in stirred tank bioreactors – larger volumes imply higher stirring speeds to ensure the mixture is homogeneous – which can impair the attachment of cells to microcarriers, causing collisions and cell damage.

Therefore, it is necessary to predict the hydrodynamic behavior in bioreactors of different sizes and their interaction with biological reactions to ensure scale-up success and mixing efficiency. The use of Computational Fluid Dynamics (CFD) allows us to understand and adjust these phenomena, making scale-up more efficient and minimizing problems, optimizing the performance of industrial bioreactors.

Use of Computational Fluid Dynamics (CFD) in Bioreactor Design

Computational Fluid Dynamics (CFD) can provide detailed modeling of hydrodynamics and mixing to properly size both the process and the equipment. In this scenario, Simcenter STAR-CCM+ offers complete solutions, allowing simulation of not only fluid dynamics, but also chemical reactions and heat transfer, using multiphysics coupling. This makes it possible to more accurately model the physical and chemical dynamics of bioreactors, addressing mixing and performance challenges in an optimized way.

In the following topics, we will explore case studies that apply CFD to bioreactors using STAR-CCM+, demonstrating how this technology can predict and optimize key variables such as mixing efficiency and liquid accumulation.

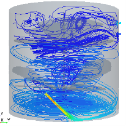

Mass Transfer in Gas-Liquid Flows

Mass transfer in gas-liquid flows is a common phenomenon in the chemical and bioprocess industries. In this case, air is considered to be dispersed in water, through which oxygen dissolves in the water. This is a very important process for bioreactor applications , playing a role in maintaining optimal conditions for biological processes.

To model this process, the Eulerian multiphase approach was used, together with a population balance model to capture the bubble size distribution. The liquid and gas phases were treated as multicomponents to account for oxygen dissolution, with turbulence modeled by the KE model and the dispersed phase flow by the Issa model. Interphase interactions were described by drag and turbulent dispersion models, while Henry's Law was used to calculate mass transfer.

The results showed that gas hold-up, i.e., the ratio between gas volume and tank volume, is a key metric for phase interaction. A higher hold-up increases the interfacial area and mass transport. The dissolved oxygen fraction converged to the saturation value (~8.24 mg/L at 25°C), and the simulation showed a higher gas concentration around the impeller axis due to centrifugal action, with less gas in the peripheral areas. These results highlight the efficiency of the modeling and its importance in gas-liquid interaction to optimize industrial mass transfer processes.

Design Optimization at the Innovation Process Center

In the case study conducted by the Innovation Process Center, a design exploration approach was adopted to identify solutions that would deliver significant performance improvements before building physical prototypes. This method allowed for a more accurate and efficient analysis of design options, saving resources and time.

Among the improvements achieved, a 40% increase in mixing performance within the system stands out, which resulted in a significant reduction in costs and time required for development. In addition, the oxygen supply in the process was optimized, achieving an overall increase of up to 17%, which contributed to improving the reactor's efficiency.

The optimization process involved evaluating a complex range of parameters to maximize reactor performance. This was done by constructing a physics pipeline that analyzed velocity, mass transfer, and species present in the system for a variety of parameters. This significantly narrowed down the testing options, focusing on those alternatives with the highest chance of success. The criterion with the greatest impact identified was oxygen transfer rate, which is essential for optimal system performance.

As engineer Alex Smith pointed out, “Instead of testing 25 options, we can focus on the ones that have the highest chance of success, saving time and cost.” This approach has resulted in a faster, more efficient design process.

Improving Bioreactor Efficiency at the University of Los Andes

The University of Los Andes conducted a case study with the aim of improving the efficiency of bioreactors in its wastewater treatment plant. To achieve this goal, the CFD simulation method was used in the design of bioreactor mixing vessels, seeking to optimize process performance. The analysis focused on improving mixing efficiency in the reactor and reducing energy consumption.

The challenge was to perform CFD analysis based on injection points, designing different configurations and adding baffles to improve mixture homogeneity.

The simulation results revealed unnecessary energy consumption in the current reactor, highlighting the need for system adjustments. Various jet agitation configurations and the inclusion of baffles were tested to explore the design space and identify the most efficient solution. The final design was able to balance sufficient mixing, adequate residence time, and reduction of process short circuits. Furthermore, the best solution was identified using the virtual model, allowing for a significant reduction in operating costs.

The impact of the project was remarkable. According to Jorge Lopez of the University of Los Andes, “it is possible to obtain a homogeneous mixture in an anaerobic MBR system without the need to include a mechanical agitator.” The study demonstrated a 50% reduction in energy consumption , reinforcing the effectiveness of using CFD simulation to optimize industrial processes and reduce energy costs.

In conclusion, the use of advanced CFD techniques and software with STAR-CCM+ has proven to be essential for the characterization and optimization of bioreactor flows. Through detailed modeling, it is possible to improve mixing efficiency, minimize stresses on organisms, optimize mass transfer and reduce energy consumption. Case studies demonstrate that CFD simulation allows identifying effective solutions to design and scale-up challenges, resulting in more efficient and productive processes, saving time and resources.

Interested in improving the performance of your bioreactors and optimizing industrial processes? Schedule a meeting with CAEXPERTS and find out how our advanced Computational Fluid Dynamics (CFD) solutions using Simcenter STAR-CCM+ can help you characterize and optimize flows, saving time and resources in the development of your project.

WhatsApp: +55 (48) 988144798

E-mail: contato@caexperts.com.br

References

DELAFOSSE, Angélique et al. CFD-based compartment model for description of mixing in bioreactors. Chemical Engineering Science, v. 106, p. 76-85, 2014.

WERNER, Sören et al. Computational fluid dynamics as a modern tool for engineering characterization of bioreactors. Pharmaceutical Bioprocessing, v. 2, n. 1, p. 85-99, 2014.