CFD simulation at your Christmas dinner

- Dec 23, 2025

- 5 min read

Christmas is a time marked by gatherings, celebrations, and, of course, the preparation of traditional dishes. Among them, roast turkey occupies a prominent place. But what happens inside the oven while the roast is being prepared?

To answer this question in a technical and accessible way, a simulation was performed using Simcenter FLOEFD, a Computational Fluid Dynamics (CFD) software, with the aim of analyzing air circulation and heat distribution in a convection oven during the preparation of a turkey.

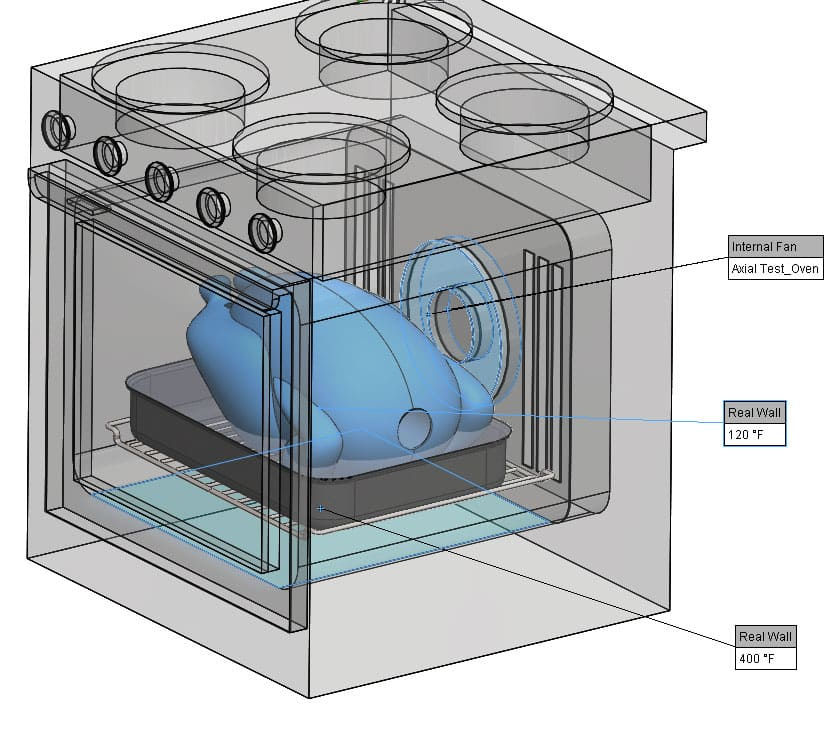

Model of a turkey in a convection oven in Simcenter FLOEFD

The simulation scenario

The turkey did not have exactly the correct dimensions, being just a solid block. There was no cavity for stuffing or for the neck, therefore the measurements were estimated visually and some cuts were made. As one of the most relevant issues was the amount of airflow through different spaces (in the cavities and under the turkey), some objects were created to collect this data. The oven was configured in convection mode, with a fan located at the rear, responsible for propelling air horizontally over the roasting area. For this model, the height of the rack is set at just over 1mm above the bottom of the roasting pan.

Turkey cavity

This model was run as a snapshot, meaning the turkey temperature was set at a point where it was not yet fully cooked (120°F). The oven temperature was set to 375°F, with the heating elements positioned at the bottom of the oven operating at a slightly higher temperature of 400°F.

Boundary Conditions for Turkey Roaster Analysis

Initially, the flow lines are observed, which are analogous to the smoke lines shown in wind tunnel tests used in car commercials. These lines indicate the direction of airflow. The fan was defined as the starting point of the flow lines.

Although the flow lines exhibit quite chaotic behavior, it is possible to extract relevant information from them. By sectioning the model, the interior of the roaster and the turkey cavity become visible. Compared to the flow lines outside the turkey, it is observed that little air enters the roaster and passes under the turkey, and an even smaller amount passes through the interior of the turkey.

This result was expected, especially regarding the airflow in the cavity. The fan propels the air transversely to the width of the turkey, not along its length. For the air to enter the cavity, it would be necessary to go around the turkey and then make a 180-degree turn, which is not physically plausible. Furthermore, due to the large size of the turkeys, it is not possible to orient them in the same direction as the airflow generated by the fan.

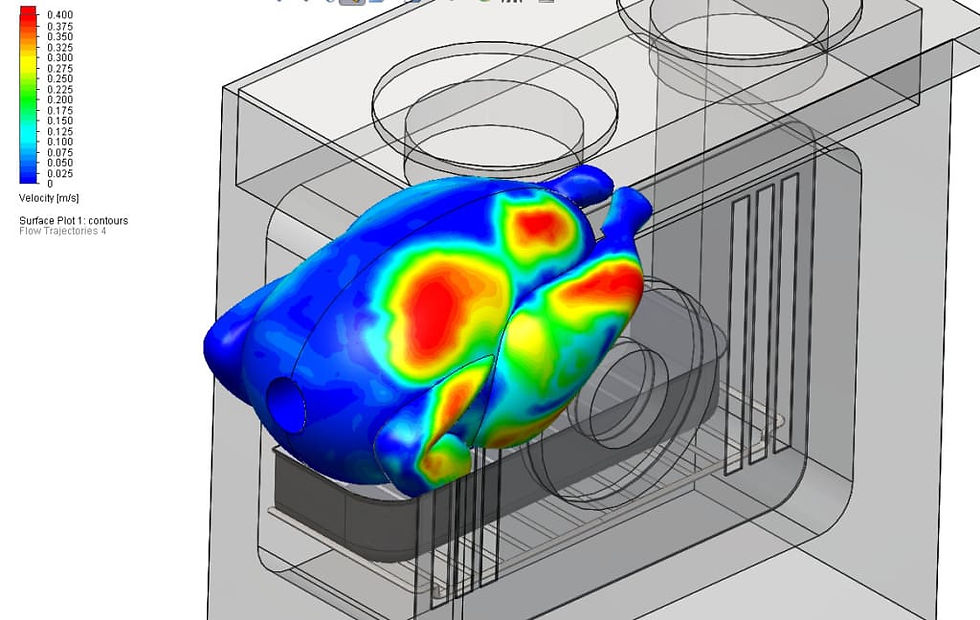

The airflow from the oven fan surrounds the turkey, whose color varies according to the temperature

The oven fan's airflow is directed towards the roasting pan and the turkey cavity

Observing a contour plot of air velocity passing through the central plane of the turkey and the oven, it can be seen that the air velocity through and under the turkey is very low, while higher values are observed above the turkey and below the roasting pan.

Low-velocity air is considered to be air whose magnitude is comparable to that of a natural convection oven, where the typical air velocity is on the order of 0.2 m/s. Therefore, there is no significant gain in heat transfer provided by the fan, since most of the turkey's surface is subjected to air velocities below 0.2 m/s.

Air Velocity Contour Graph

For a more precise understanding of this behavior, a graph of the air velocity near the surface of the turkey is observed. The image has been divided into two parts: one representing the surface of the turkey facing the fan and the other showing the opposite side. The difference between the two regions is evident.

As a consequence, one side of the turkey tends to cook or dry out more quickly than the other if the food is not rotated periodically. Higher air velocities result in more intense convection, a principle illustrated by the act of blowing on soup to accelerate its cooling.

Speed close to the surface of the turkey, near the fan

Air velocity near the surface of the turkey, opposite to that of the fan.

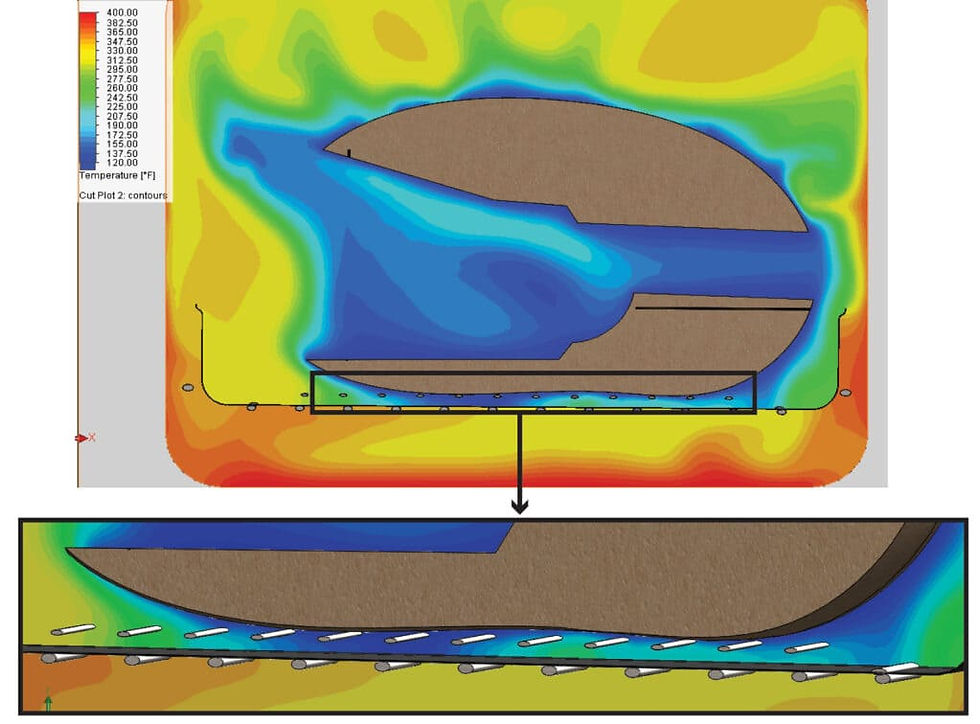

Returning to the contour plot, when analyzing the temperature distribution, it is clearly observed that the air inside the turkey has significantly lower temperatures. This occurs due to air stagnation, since there is no effective circulation of hot air inside the turkey.

It is also observed that, below the turkey, in the space of approximately 1 cm (0.4 inches) provided by the grill, the air temperature is lower than that of the rest of the oven. Again, this behavior is explained by the limited circulation of renewed hot air in this region.

Air temperature contour graph along the centerline of the turkey

The question arises as to why air has difficulty penetrating the space between the turkey and the bottom of the roasting pan. Observation of the flow lines indicates that the cause is essentially the same as that which prevents air from entering the inside of the turkey. The air from the fan tends to follow the path of least resistance.

To flow under the turkey, the air would need to go around the wall of the roasting pan, descend through the space between the turkey and that wall, and then make a 90-degree turn to flow under the turkey. Along this path, there is a reduction in speed and a loss of temperature. Both factors are relevant, since colder air tends to descend.

Furthermore, since the flow velocity is lower than that of a natural convection current, the warm, renewed air cannot displace the air already present in that region. For this reason, it is observed that the air reaches the roasting pan, but cannot advance under the turkey, instead recirculating near the wall of the roasting pan.

Contour graph of air velocity and streamlines along the width of the turkey

The images provide a good qualitative understanding of the phenomenon; however, in many cases, a quantitative analysis is necessary. Data evaluation indicates that the oven fan moves approximately 22.8 CFM of air. The airflow that effectively enters and exits the roaster is about 0.35 CFM, which corresponds to approximately 1.5% of the total fan flow.

Regarding the air entering the turkey cavities, the inflow and outflow were analyzed in both the neck cavity and the larger rear cavity. The measured flow rates were 0.08 CFM and 0.146 CFM, respectively.

From these results, it is concluded that the stuffing is not responsible for preventing air circulation inside the turkey, since this circulation is already intrinsically very limited. This does not exclude the effect of the additional thermal mass of the stuffing, which can result in longer cooking times and drier meat—a topic that deserves specific analysis.

Nor should one expect significant air circulation under the turkey capable of producing a completely crispy skin. A higher rack or a roasting pan with lower sides might offer some improvement, although this effect is questionable. In practice, using a rack or vegetables like carrots, celery, or potatoes serves a similar function, elevating the turkey and keeping it away from the accumulated fat.

Want to understand how simulation can bring that same level of technical analysis to the real-world challenges of your engineering? Schedule a meeting with CAEXPERTS and discover how CFD and advanced simulation solutions can optimize your projects and processes. We also take this opportunity to wish you a Merry Christmas and a Happy New Year! 🎄✨

WhatsApp: +55 (48) 98814-4798

E-mail: contato@caexperts.com.br